- info@esummitsb.com

- +603 - 3343 6181

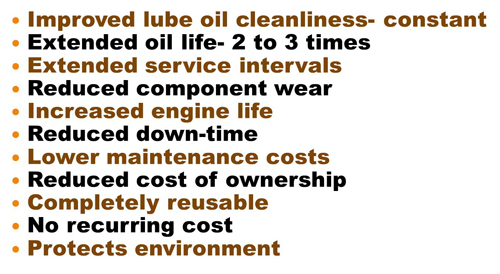

Advantage of Oilmax Centrifugal Oil Cleaner over convention filter

Benefits of Oilmax Centrifugal system

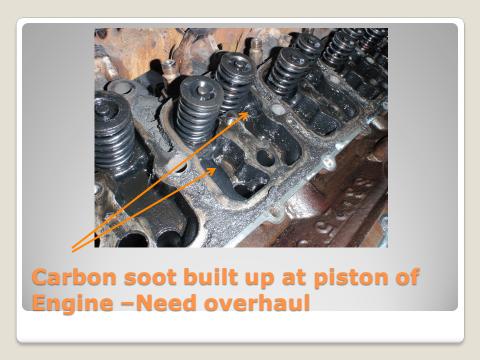

Customer reference after installation for two years, engine still looks new and clean without any needs of overhaul

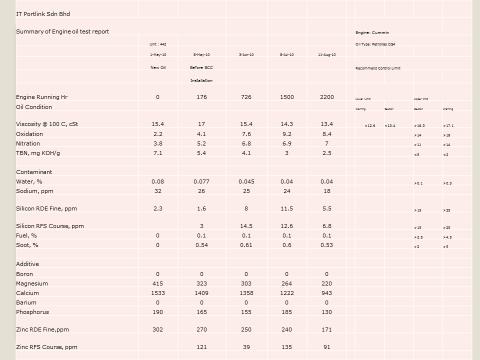

Oil Test Report at different time interval for a diesel engine after installed Oilmax centrifugal at 176 hour, since the change of new engine oil.

The oil lasted 2200 hours and all specification still within requirement

Selection Chart

| Centrifuge Model | Nominal Flow Rate | Dirt Holding Capacity | Suitable for Engine Oil Sump Capacity |

|---|---|---|---|

| SCC 020 | 200 LPH | 200 cc | 20 Ltrs |

| SCC 025 | 250 LPH | 250 cc | 30 Ltrs |

| SCC 050 | 450 LPH | 500 cc | 50 Ltrs |

| SCC 075 | 700 LPH | 750 cc | 75 Ltrs |

| SCC 100 | 1000 LPH | 1000 cc | 100 Ltrs |

| SCC 200 | 1200 LPH | 2000 cc | 500 Ltrs |

| SCC 600 | 4000 LPH | 6000 cc | 2000 Ltrs |